Why don’t commercial Class 8 trucks have hydraulic brakes like the automotive world? The main answer to this question is safety. The model air brake system on commercial vehicles is incredibly reliable and can apply the braking force to slow 80,000 pounds of truck, trailer and cargo in a relatively short distance. Air brake systems are standard equipment on all makes/models of Class 8 trucks, and operate using the same principals, regardless of manufacturer.

Commercial vehicles with air brakes all contain the following list of components:

- Air compressor: Pumps the air into the reservoir tanks to be used in the brake system

- Air compressor governor: Controls the cut-in and cut-out point of the air compressor to maintain a set amount of air in the tank or tanks

- Air reservoir tanks: Hold compressed or pressurized air to be used by the braking system

- Drain valves: Release valves in the air tanks used to drain the air when the vehicle isn’t in use

- Foot valve (brake pedal): When depressed, air is released from the reservoir tanks

- Brake chambers: Cylindrical container that houses a slack adjuster that moves a diaphragm or cam mechanism

- Push rod: A steel rod similar to a piston that connects the brake chamber to the slack adjuster. When depressed, the brakes are released. If extended, the brakes are applied.

- Slack adjusters: An arm connects the push rod to the brake s-cam to adjust the distance between the brake shoes

- Brake S-cam: An s-shaped cam that pushes brake shoes apart and against the brake drum

- Brake shoe: Steel mechanism with a lining that causes friction against the brake drum

- Return spring: A stiff spring connected to each of the brake shoes that returns the shoes to the open position when not spread by the s-cam or diaphragm.

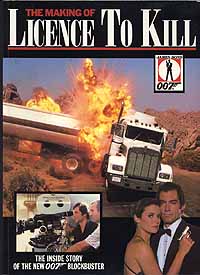

So how do all these items come together to work on a commercial truck? The trucks engine when running is also running the air compressor. The air compressor pumps air into the air reservoir tanks building up air pressure in the tanks until the air compressor governor cuts out the pressure to the tanks (usually 120 psi). When you first start a truck with no air pressure you will hear a buzzer/alarm to warn you that air pressure is low. Once the truck builds up appropriate air pressure the buzzer/alarm will go off and you will be able to depress the dash valve to supply air to release the brakes. That’s the beauty of the air brake system. If the system malfunctions and you lose air pressure the brakes are applied and the vehicle either won’t move, or it will come to a stop. For those of you who are fans of the James Bond movies, you’ll remember how Timothy Dalton at the end of “License to Kill” is in dramatic fight with the evil drug lord Franz Sanchez. During this fight scene an air line connecting the tractor and trailer is cut causing a loss of air pressure. Had the movie correctly showed how truck air brakes work the truck would have slowed to a stop preventing the truck from speeding out of control over a cliff.

So how do all these items come together to work on a commercial truck? The trucks engine when running is also running the air compressor. The air compressor pumps air into the air reservoir tanks building up air pressure in the tanks until the air compressor governor cuts out the pressure to the tanks (usually 120 psi). When you first start a truck with no air pressure you will hear a buzzer/alarm to warn you that air pressure is low. Once the truck builds up appropriate air pressure the buzzer/alarm will go off and you will be able to depress the dash valve to supply air to release the brakes. That’s the beauty of the air brake system. If the system malfunctions and you lose air pressure the brakes are applied and the vehicle either won’t move, or it will come to a stop. For those of you who are fans of the James Bond movies, you’ll remember how Timothy Dalton at the end of “License to Kill” is in dramatic fight with the evil drug lord Franz Sanchez. During this fight scene an air line connecting the tractor and trailer is cut causing a loss of air pressure. Had the movie correctly showed how truck air brakes work the truck would have slowed to a stop preventing the truck from speeding out of control over a cliff.

So how does applying air pressure to the tanks cause the brakes to release? The air valve in the dash allows air pressure to travel through the brake lines. The air pressure forces the diaphragm to push the “push rod” enough distance to turn the slack adjuster which is connected to the S-Cam to force the brake shoes to be pulled away from the brake drum allowing the truck to move. While this may sound complicated the main point is that air pressure releases the brakes from the drum, a reduction of air pressure (pressing the brake pedal) causes the brake shoes to contact the drum forcing the vehicle to slow down.

Know that you know the basics of how air brakes work. What steps do you need to do to keep the air brakes maintained?

Daily Inspection:

- As part of a driver’s daily pre-trip inspection they should ensure that the truck builds air quickly and does not have any leaks. To do this check start the truck, watch the air pressure gauge and ensure the trucks builds air quickly. Once the truck has reached full air pressure, release the parking brakes (push the dash valve in) and then turn the engine off so you can listen and check for any leaks. Apply the foot valve (brake pedal) and listen for any air leaks. As you hold the pedal down watch the air pressure gauge. If there is an air leak you will notice the gauge continuing to drop. If this happens the truck needs to be inspected by a trained technician. If the air pressure holds steady then start pumping the brake pedal, as the air pressure decreases you will hear the buzzer/alarm and if you continue to pump the brakes decreasing the air pressure more, the dash valve will pop out fully applying the parking brakes.

- Find the location of the air tanks and pull the drain valve, you will hear air hiss out of the tank. If you notice water in the tank, keep draining the tank till all of the water is out of the tank. If you truck is equipped with an air dryer and you notice water in the air tanks, you should contact a trained technician to replace the air dryer cartridge to keep the air brake system dry. Water in the brake system can freeze in cold weather blocking air lines

- For tractor/trailers you should inspect the glad hands that connect the air hoses from the tractor to the trailer. Make sure the glad hands rubber gaskets are in good condition. A failed rubber gasket will cause and air pressure to leak from the brake system.

Periodic Inspection:

These items should be inspected by a trained technician during regular scheduled maintenance.

- Inspect the brake lining to ensure the brakes have enough friction material to stop the vehicle.

- Inspect the brake chambers and slack adjusters to ensure the brakes are properly adjusted to allow full brake pressure.

- Inspect all air brake lines for rubbing. A line that is rubbing against something will eventually wear though causing a loss of air pressure.

By following these simple steps you can be certain the next time you need your truck to stop, everything will work properly keeping you and the people you share the road with safe.

nice post. thanks.

This is such a great resource that you are providing and you give it away for free. I enjoy seeing websites that understand the value of providing a prime resource for free. I truly loved reading your post. Thanks!

After reading you site, Your site is very useful for me .I bookmarked your site!

really appreciate YOU — thanks a lot!

thanks for great informations It’s a wonderful

wow.. i’m very

enjoy reading your post. great.

Quite right! It is good thought. I call for active discussion.

great share, great article, very usefull for me…thank

you

I searched for something completely different, but found your website! And have to say thanks. Nice read. Will come back.

nice share, good article, very usefull for me…thanks

Of course, what a great site and informative posts, I will add backlink – bookmark this site? Regards, Reader.

One again, your idea is very

good.thank you!very much.

Nice content. Thank you for your information.

very well information you write it very clean. I’m very lucky to get this info from you.

Good post and this mail helped me alot in my college assignement. Gratefulness you seeking your information.

great post as usual!

Thanks for good news!

thanks for great informations It’s a wonderful

i am happy to find it thanks for sharing it here. Nice work.

Valuable info. Lucky me I found your site by accident, I bookmarked it.

thanks for great informations It’s a wonderful

Thanks for good information that comes out to

read.

I’ve recently started a blog, the information you provide on this site has helped me tremendously. Thank you for all of your time & work.

great share, great article, very usefull for me…thank you

wow.. i’m very

enjoy reading your post. great.

Thans

for the nice post.

It’s posts like this that keep me coming back and checking this site regularly, thanks for the info!

very well information you write it very

clean. I’m very lucky to get this information from you.

Very good sharing this.

found your site on del.icio.us today and really liked it.. i bookmarked it and will be back to check it out some more later

Thanks for this useful article.

How to Properly Maintain Truck Air Brakes Wheeling Truck Center Blog best post. I has been collection in my blog. 2010/00/00

How to Properly Maintain Truck Air Brakes Wheeling Truck Center BlogI bookmarked it.5/25/2010

Terrific work! This is the type of information that should be shared around the web. Shame on the search engines for not positioning this post higher!

Just want to say what a great blog you got here!

I’ve been around for quite a lot of time, but finally decided to show my appreciation of your work!

Thumbs up, and keep it going!

Cheers

Christian, iwspo.net