No company stays in business for seventy-some years without one quality – the ability to adapt to change. There was a time when we could leave the business of exporting to the likes of the coal industry, the chemical industry, the steel industry. Today if you are a medium or even a small-sized company, then you must take a serious look at overseas opportunities.” Mollohan concluded, “It is so important for our government to encourage excellence in that undertaking. I appreciate the excellent work of the Department of Commerce and the Export Assistance Center here in Wheeling.”

No company stays in business for seventy-some years without one quality – the ability to adapt to change. There was a time when we could leave the business of exporting to the likes of the coal industry, the chemical industry, the steel industry. Today if you are a medium or even a small-sized company, then you must take a serious look at overseas opportunities.” Mollohan concluded, “It is so important for our government to encourage excellence in that undertaking. I appreciate the excellent work of the Department of Commerce and the Export Assistance Center here in Wheeling.” No company stays in business for seventy-some years without one quality – the ability to adapt to change. There was a time when we could leave the business of exporting to the likes of the coal industry, the chemical industry, the steel industry. Today if you are a medium or even a small-sized company, then you must take a serious look at overseas opportunities.” Mollohan concluded, “It is so important for our government to encourage excellence in that undertaking. I appreciate the excellent work of the Department of Commerce and the Export Assistance Center here in Wheeling.”

No company stays in business for seventy-some years without one quality – the ability to adapt to change. There was a time when we could leave the business of exporting to the likes of the coal industry, the chemical industry, the steel industry. Today if you are a medium or even a small-sized company, then you must take a serious look at overseas opportunities.” Mollohan concluded, “It is so important for our government to encourage excellence in that undertaking. I appreciate the excellent work of the Department of Commerce and the Export Assistance Center here in Wheeling.”Chad Remp, operations manager at Wheeling Truck Center was recently nominated to The State Journal’s Generation Next – 40 Under 40 for 2010.

Why don’t commercial Class 8 trucks have hydraulic brakes like the automotive world? The main answer to this question is safety. The model air brake system on commercial vehicles is incredibly reliable and can apply the braking force to slow 80,000 pounds of truck, trailer and cargo in a relatively short distance. Air brake systems are standard equipment on all makes/models of Class 8 trucks, and operate using the same principals, regardless of manufacturer.

Commercial vehicles with air brakes all contain the following list of components:

- Air compressor: Pumps the air into the reservoir tanks to be used in the brake system

- Air compressor governor: Controls the cut-in and cut-out point of the air compressor to maintain a set amount of air in the tank or tanks

- Air reservoir tanks: Hold compressed or pressurized air to be used by the braking system

- Drain valves: Release valves in the air tanks used to drain the air when the vehicle isn’t in use

- Foot valve (brake pedal): When depressed, air is released from the reservoir tanks

- Brake chambers: Cylindrical container that houses a slack adjuster that moves a diaphragm or cam mechanism

- Push rod: A steel rod similar to a piston that connects the brake chamber to the slack adjuster. When depressed, the brakes are released. If extended, the brakes are applied.

- Slack adjusters: An arm connects the push rod to the brake s-cam to adjust the distance between the brake shoes

- Brake S-cam: An s-shaped cam that pushes brake shoes apart and against the brake drum

- Brake shoe: Steel mechanism with a lining that causes friction against the brake drum

- Return spring: A stiff spring connected to each of the brake shoes that returns the shoes to the open position when not spread by the s-cam or diaphragm.

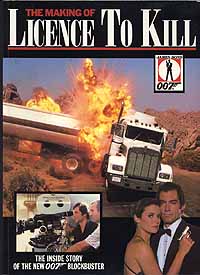

So how do all these items come together to work on a commercial truck? The trucks engine when running is also running the air compressor. The air compressor pumps air into the air reservoir tanks building up air pressure in the tanks until the air compressor governor cuts out the pressure to the tanks (usually 120 psi). When you first start a truck with no air pressure you will hear a buzzer/alarm to warn you that air pressure is low. Once the truck builds up appropriate air pressure the buzzer/alarm will go off and you will be able to depress the dash valve to supply air to release the brakes. That’s the beauty of the air brake system. If the system malfunctions and you lose air pressure the brakes are applied and the vehicle either won’t move, or it will come to a stop. For those of you who are fans of the James Bond movies, you’ll remember how Timothy Dalton at the end of “License to Kill” is in dramatic fight with the evil drug lord Franz Sanchez. During this fight scene an air line connecting the tractor and trailer is cut causing a loss of air pressure. Had the movie correctly showed how truck air brakes work the truck would have slowed to a stop preventing the truck from speeding out of control over a cliff.

So how do all these items come together to work on a commercial truck? The trucks engine when running is also running the air compressor. The air compressor pumps air into the air reservoir tanks building up air pressure in the tanks until the air compressor governor cuts out the pressure to the tanks (usually 120 psi). When you first start a truck with no air pressure you will hear a buzzer/alarm to warn you that air pressure is low. Once the truck builds up appropriate air pressure the buzzer/alarm will go off and you will be able to depress the dash valve to supply air to release the brakes. That’s the beauty of the air brake system. If the system malfunctions and you lose air pressure the brakes are applied and the vehicle either won’t move, or it will come to a stop. For those of you who are fans of the James Bond movies, you’ll remember how Timothy Dalton at the end of “License to Kill” is in dramatic fight with the evil drug lord Franz Sanchez. During this fight scene an air line connecting the tractor and trailer is cut causing a loss of air pressure. Had the movie correctly showed how truck air brakes work the truck would have slowed to a stop preventing the truck from speeding out of control over a cliff.

So how does applying air pressure to the tanks cause the brakes to release? The air valve in the dash allows air pressure to travel through the brake lines. The air pressure forces the diaphragm to push the “push rod” enough distance to turn the slack adjuster which is connected to the S-Cam to force the brake shoes to be pulled away from the brake drum allowing the truck to move. While this may sound complicated the main point is that air pressure releases the brakes from the drum, a reduction of air pressure (pressing the brake pedal) causes the brake shoes to contact the drum forcing the vehicle to slow down.

Know that you know the basics of how air brakes work. What steps do you need to do to keep the air brakes maintained?

Daily Inspection:

- As part of a driver’s daily pre-trip inspection they should ensure that the truck builds air quickly and does not have any leaks. To do this check start the truck, watch the air pressure gauge and ensure the trucks builds air quickly. Once the truck has reached full air pressure, release the parking brakes (push the dash valve in) and then turn the engine off so you can listen and check for any leaks. Apply the foot valve (brake pedal) and listen for any air leaks. As you hold the pedal down watch the air pressure gauge. If there is an air leak you will notice the gauge continuing to drop. If this happens the truck needs to be inspected by a trained technician. If the air pressure holds steady then start pumping the brake pedal, as the air pressure decreases you will hear the buzzer/alarm and if you continue to pump the brakes decreasing the air pressure more, the dash valve will pop out fully applying the parking brakes.

- Find the location of the air tanks and pull the drain valve, you will hear air hiss out of the tank. If you notice water in the tank, keep draining the tank till all of the water is out of the tank. If you truck is equipped with an air dryer and you notice water in the air tanks, you should contact a trained technician to replace the air dryer cartridge to keep the air brake system dry. Water in the brake system can freeze in cold weather blocking air lines

- For tractor/trailers you should inspect the glad hands that connect the air hoses from the tractor to the trailer. Make sure the glad hands rubber gaskets are in good condition. A failed rubber gasket will cause and air pressure to leak from the brake system.

Periodic Inspection:

These items should be inspected by a trained technician during regular scheduled maintenance.

- Inspect the brake lining to ensure the brakes have enough friction material to stop the vehicle.

- Inspect the brake chambers and slack adjusters to ensure the brakes are properly adjusted to allow full brake pressure.

- Inspect all air brake lines for rubbing. A line that is rubbing against something will eventually wear though causing a loss of air pressure.

By following these simple steps you can be certain the next time you need your truck to stop, everything will work properly keeping you and the people you share the road with safe.

Recently we’ve seen the values of used truck decrease to

record lows, and at the same time, we are seeing large increases in new truck

prices due to EPA regulations. This is creating an opportunity to look at

buying used trucks as a sensible alternative to buying new. Many trucking

companies may still don’t believe that buying a used truck is a viable

alternative to buying new.

Buying New

Buying a new truck gives you a warranty usually 1 year for

the chassis and 3-5 years for the engine and major components. Buying a new

truck also gives you new brakes, drums, tires, and all wearable components are

brand new allowing you to drive the truck for at least a year before performing

any maintenance besides oil changes, and grease. Your new truck will also give

you 4-6 years of low cost ownership as most the major components will not need

any repairs.

Buying Used

When reviewing the list above for reasons to buy a new

truck, it’s hard to see a good reason to buy a used truck. Here’s the main

reason – $$$, cash. While a tandem axle sleeper highway truck new will cost

from $110,000 to $150,000 (depending on options), a 4-5 year old similar speced

unit will cost 1/3 the price ($38,000 to $50,000). With the money you save in

buying used, you can use to offset the costs of additional repairs and

maintenance that a used truck will demand.

7 Tips on buying a Used Truck

1. Are maintenance records available – by reviewing maintenance

records you may be able to find out if the vehicle has had reoccurring

problems that may be from a lack of maintenance. Also were the parts used in

repairing the truck OEM parts, or were they counterfeit parts? While

counterfeit parts may look like OEM parts, they are not, and you risk

premature failure of the counterfeit part, causing you unnecessary downtime.

By researching the maintenance records you can also spot any mileage

discrepancies. You don’t want to find out that 300,000 mile truck is actually

a 600,000 mile truck after you’ve bought it. Also don’t get discouraged if

the truck has had minor wreck damage, or breakdowns. These things are to be

expected. I would worry more if someone told me in 300,000 miles they only

changed the oil on the truck, and it never broke down.

2. Is a warranty available – Nothing could be worse than buying a

truck and having a major breakdown early in ownership. Many dealers offer

used truck warranties that will cover components for 1-2 years. While you may

have to pay out of pocket for minor repairs, a major repair like a

transmission or engine overhaul may be covered under the used truck warranty

saving you $.

3. What is the condition of the Tires/Brakes/Drums – Tires, Brakes,

and Drums are all maintenance items that will need replaced from time to

time. By knowing the condition of these items you will know how long you will

be able to drive the truck before incurring your first major maintenance

bill. A truck with deep rubber and new/newer brakes, drums will save you $ as

you will not have to replace these items until later.

4. Inspection/Condition of the truck – Find out will the truck pass a

DOT Inspection on its first trip with you? Have the dealer place an updated

DOT inspection sticker in the truck.

5. Financing – While you can expect to pay higher interest rates, and

have a shorter term for used trucks, watch the fine print. Don’t ever pay

money up front with an application. The only time you should hand money over

is if you will be receiving the truck minutes later. In addition make sure

the repayment schedule is known upfront (# of payments, principal/interest for

each payment, and any final payment cost), are there balloon payments, how is

the interest amortized? Make sure you do your homework upfront to prevent

paying forever on a truck you’ll never own.

6. Insurance – Many buyers of used trucks are owner-operators, or

small fleets that often are hired by larger fleets. Does your fleet offer and

insurance program for you? While the fleets insurance policy may be good you

need to find out if you can do better on your own. Shop your insurance

policy, make sure you have bobtail coverage (coverage if you’re not hauling a

load). What are your deductibles? Will they rent you a truck if yours has

been wrecked? Can you afford your deductible? Do you need GAP insurance?

These are just some of the questions you need to ask a licensed insurance

professional to ensure you are not setting yourself up for failure.

7. Common Sense – If a truck looks too good to be true for the price,

maybe it is. If nobody else can get you financed, and someone does get you

financed at a great rate, maybe something isn’t ok.

While this list is not everything you need to check on a

buying a used truck, hopefully it helps you out with your next purchase. Is

there anything you always look for before buying a used truck? I’d love to hear

your feedback.

To check out Wheeling Truck Center’s Used Truck Inventory check us out online, or call us 304-232-1440

Welcome to Wheeling Truck Center’s Blog. We will post information about the heavy-duty truck industry, and how Wheeling Truck Center is helping keep our customers on the road.